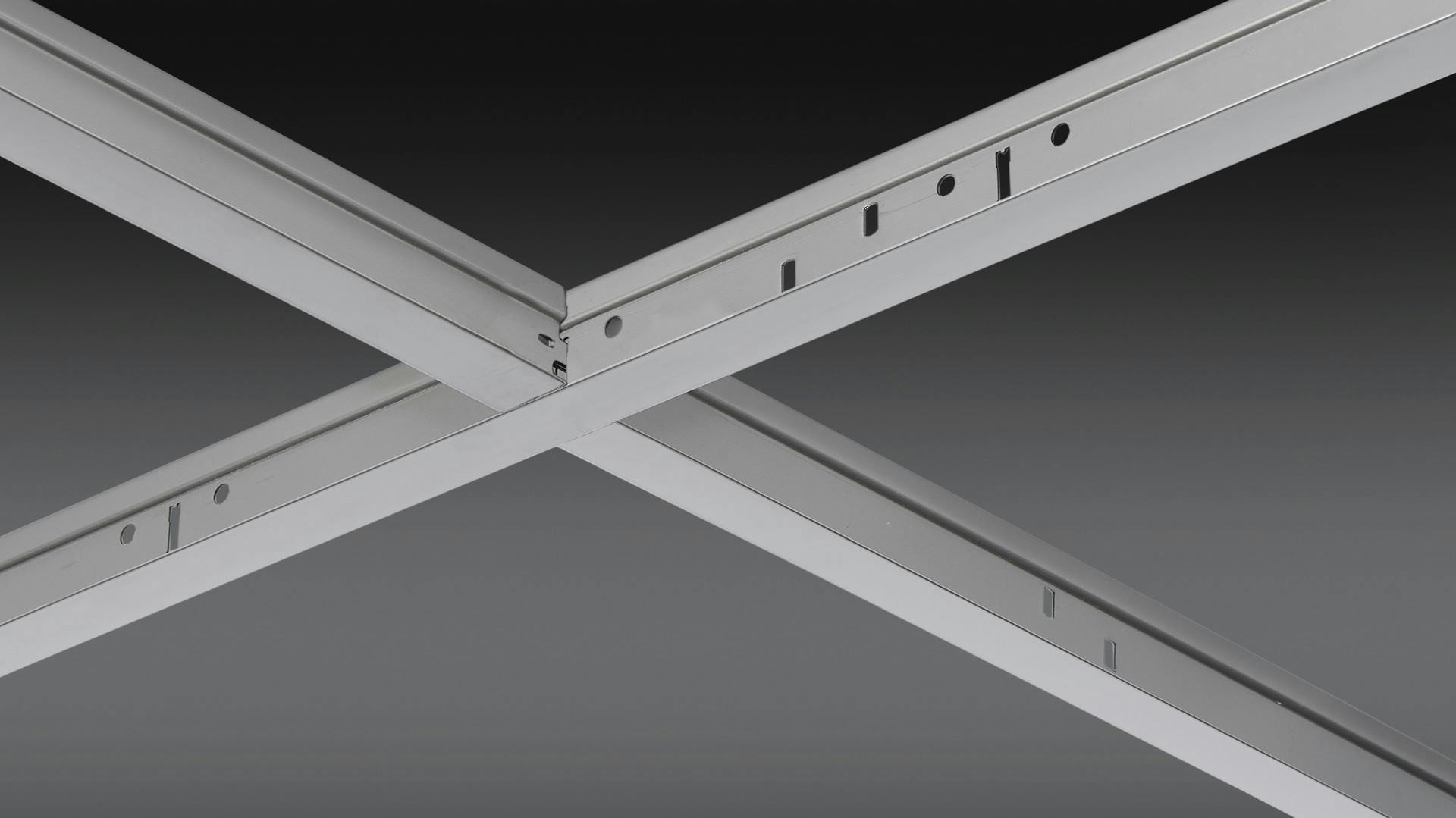

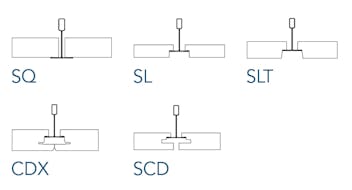

Chicago Metallic® 730 Stainless Steel 15/16" Exposed grid ceiling system is available in an intermediate-duty design, is roll formed entirely from 304 stainless steel, and is the most resistant of the Chicago Metallic™ grid systems to corrosion. Featuring demountable hook-end cross tees, this designer ceiling grid assembles quickly and easily. Chicago Metallic™ grid systems are third party certified to meet ASTM standards and are listed with ICCES Evaluation Services, reference report ESR-2631 for more information.

Performance Properties:

-Designer grid system features an intermediate-duty design with hook-end cross tees

-Acoustical ceiling system uses 304 stainless steel design and 2B Finish Stainless steel capping

-Sturdy stainless steel grid construction provides superior corrosion resistance

-All system components are shipped with strippable plastic film to protect exposed grid face

-Chicago Metallic® suspension systems meet a Class-A flame spread rating in accordance with ASTM standard E1264-08

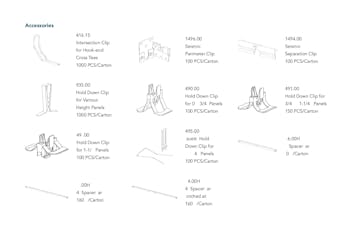

For packaging information, please download datasheet.